头部邮箱+阿里巴巴

Welcome to Luwei official website!Tel:+86-592-7072928 E-mail: tina.ye@xmlwjx.com

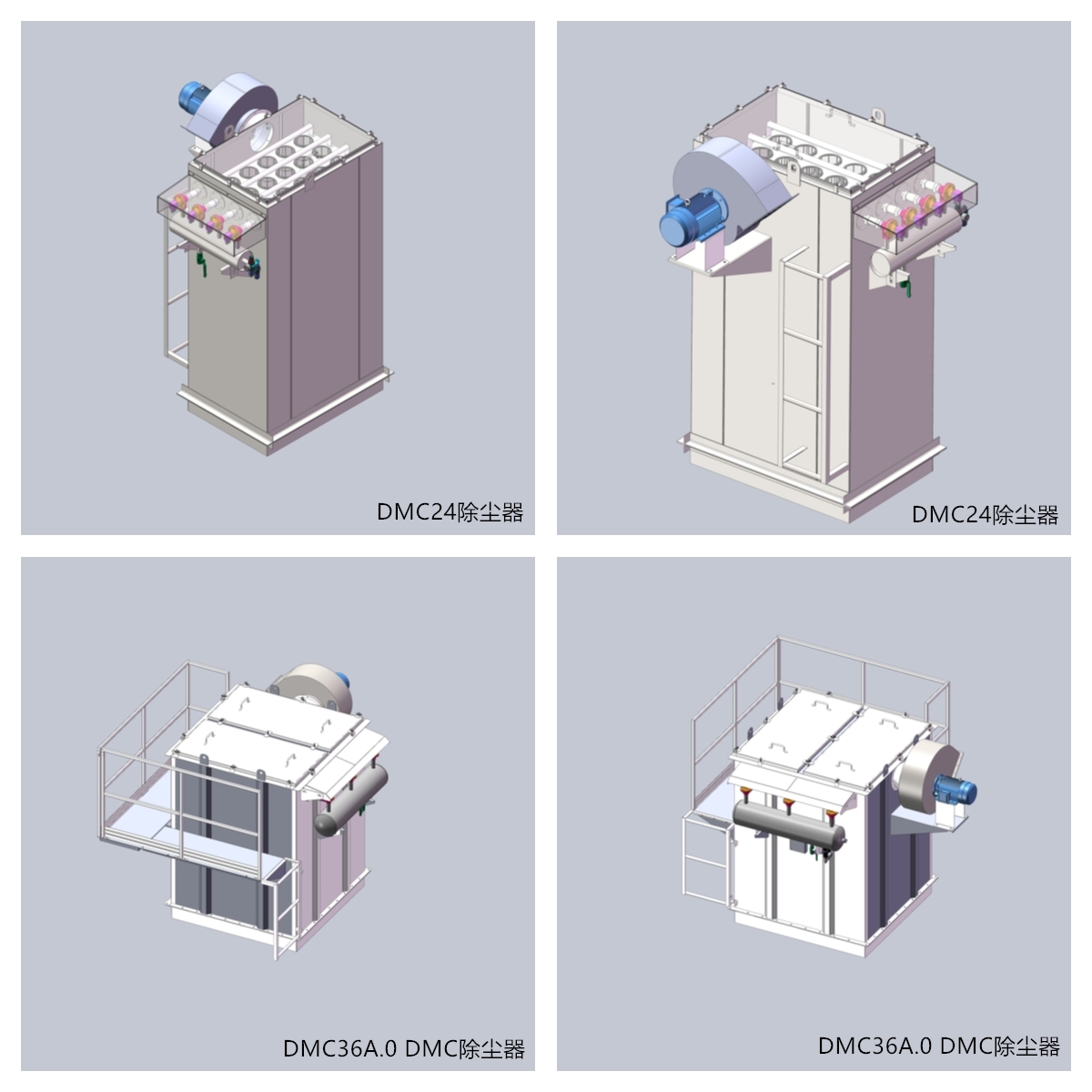

Pulse bag dust collector(ement silo dust collector,cement dust collector,Pulse bag dust collector)

Introduction :Xiamen Luwei Construction Equipment Co., Ltd.specializes in the production of Pulse bag dust collector ,industrial baghouse dust collectors,Industrial dust removal,with a global market coverage .

Application:

The pulse bag dust collector has a wide range of applications in the mining, metallurgy, machinery, building materials, chemical, light industry and other industrial sectors. Its working principle is that when the gas containing dust passes through the filter bag, only the gas is allowed to pass through due to the filtering effect, and the dust is blocked on the surface of the filter bag to achieve the purpose of dust removal. Compared with other dust collectors, the bag filter has the advantage of higher filtration efficiency, generally above 99.99%. Therefore, the gas discharged from the dust collector contains less dust and can meet the requirements of environmental protection emission standards; in the filter speed selection when the dust removal method is appropriate and the dust removal method is appropriate, the change of the inlet dust concentration has little effect on the dust removal efficiency and pressure loss; the equipment has high operating stability and strong adaptability; it is convenient to recover useful materials and realize comprehensive utilization.

Features:

Under the power of the fan, the pulse bag filter creates a negative pressure environment inside the dust collector, the dust removal pipe and the dust removal hood, so that the dust at the dust point enters the dust collector under the pressure difference, and the dust-containing gas enters the dust removal through the air inlet After the filter, the airflow speed slows down, and the coarse particles leave the airflow and settle into the dust collection chamber. The fine dust is blocked on the outer surface of the bag when the airflow passes through the bag, and the clean gas is discharged from the air outlet; when the dust layer on the surface of the bag is thick, pulse The controller sends a command to open the injection valve, and the compressed air in the air bag is ejected at a high speed through the injection pipe, and at the same time, it induces several times the amount of surrounding air to enter the bag, and shoots out quickly from the inside to the outside, blowing down the dust on the outer surface of the bag. Into the dust collection chamber, and finally discharged from the ash hopper. The dust collector adopts the pulse spraying method to clean the dust completely without damaging the filter bag, so that the service life of the filter bag can be guaranteed. The ash cleaning process is automatically controlled by a pulse controller, which can be controlled by pressure difference or time.

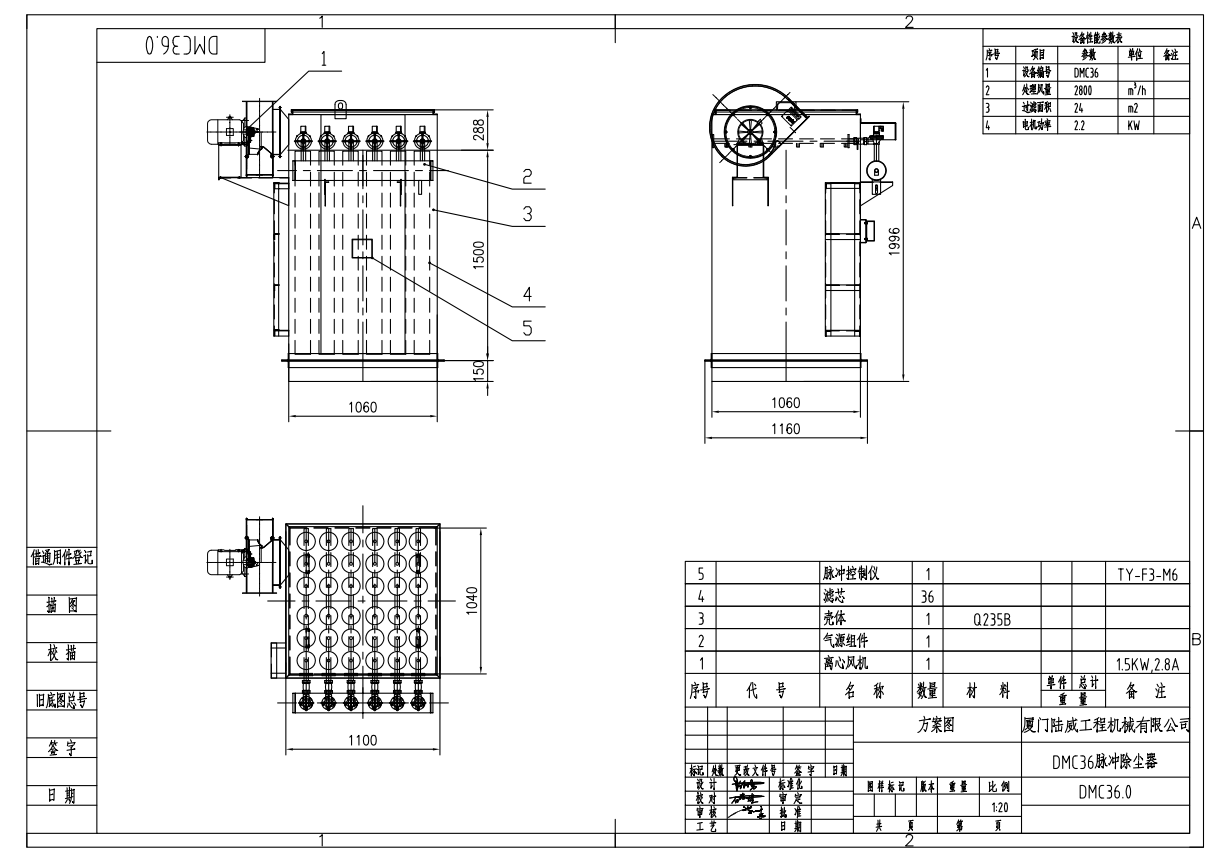

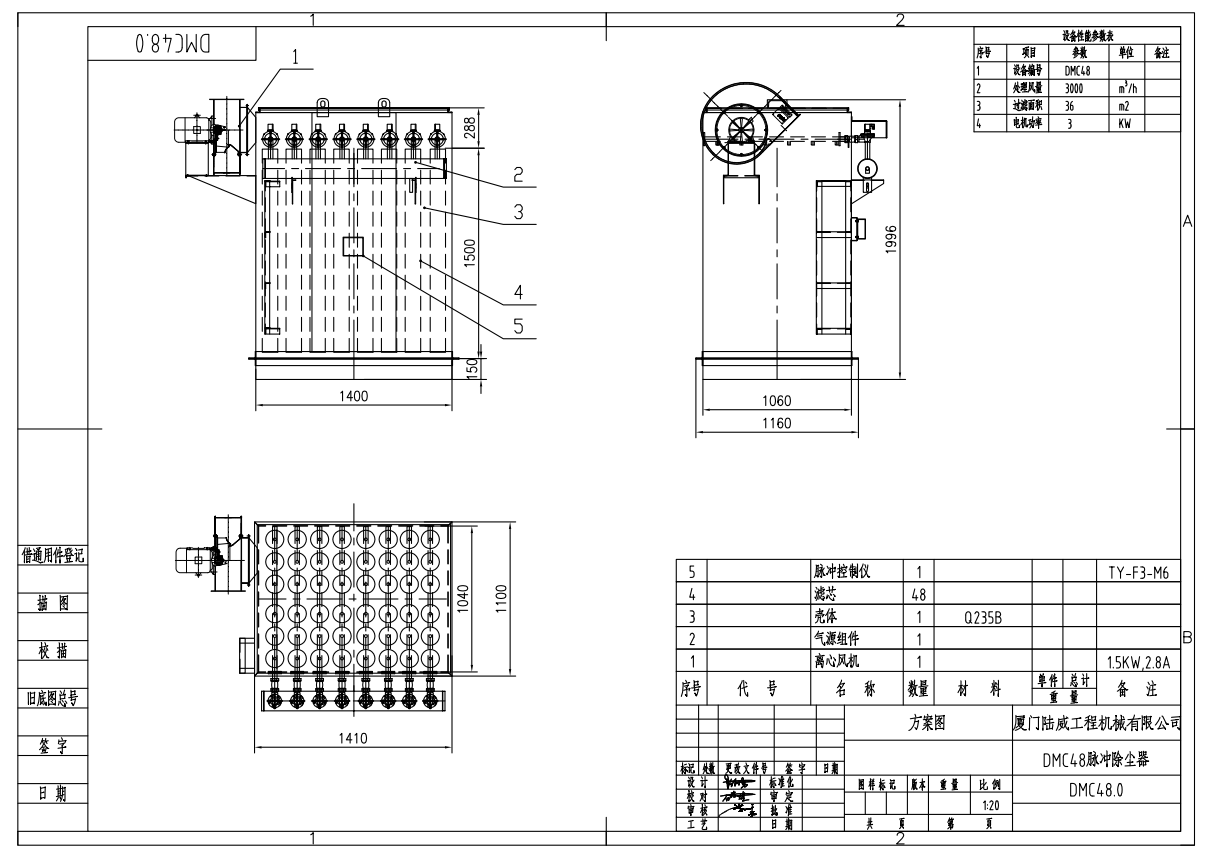

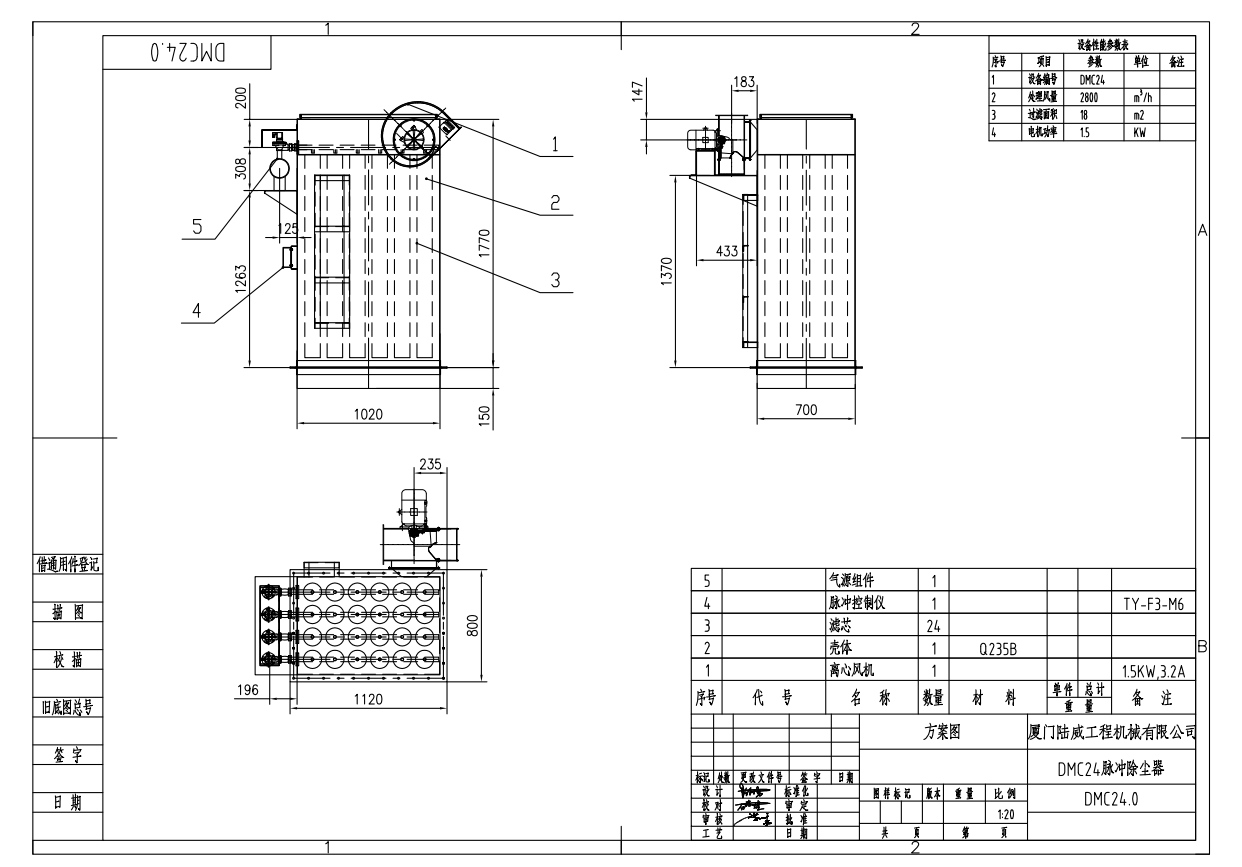

| 设备型号 | 处理风量(m³/h) | 滤袋数量(只) | 过滤面积(㎡) | 电机功率(Kw) |

| DMC 24 | 540-2160 | 24 | 18 | 1.5 |

| DMC 36 | 810-2880 | 36 | 24 | 2.2 |

| DMC 48 | 1080-3240 | 48 | 36 | 3 |

Scan and follow Lu Wei

Scan and follow Xiang Hao

Scan and follow Zhi Xiang

Xiamen Luwei Prefabricated

Steel Structure Co., Ltd Ltd.

Service Hotline:

+86 592-7072928 / +86 18150889219 (Tina Ye) (Overseas)

E-mail:tina.ye@xmlwjx.com

Registered address of the company:

Office Building 3rd Floor, No.608, Xinxia

South Road, Xinxu Town, Xiang'an District, Xiamen City

Factory Address:

E3 workshop, Factory 2nd Floor, No.608, Xinxia South Road, Xinxu Town, Xiang'an District, Xiamen City

Page Copyright: Xiamen Luwei Prefabricated Steel Structure Co., Ltd Ltd. 闽ICP备10205934号

Friendly Link: Alibaba