头部邮箱+阿里巴巴

Welcome to Luwei official website!Tel:+86-592-7072928 E-mail: tina.ye@xmlwjx.com

NE/NSE bucket elevator(bucket elevator conveyor,cement bucket elevator,bucket elevator for cement plant)

Introduction :Xiamen Luwei Construction Equipment Co., Ltd.specializes in the production of bucket elevator conveyor ,cement bucket elevator,bucket elevator for cement plant,with a global market coverage .

bucket elevator conveyor,cement bucket elevator,bucket elevator for cement plant is one of the main products of Xiamen Luwei Construction Machinery Co., Ltd.with good Wholesale Price and quality, Factory direct sales are the cheap. Our company is a professional supplier and manufacturers in China, with various products For sale.

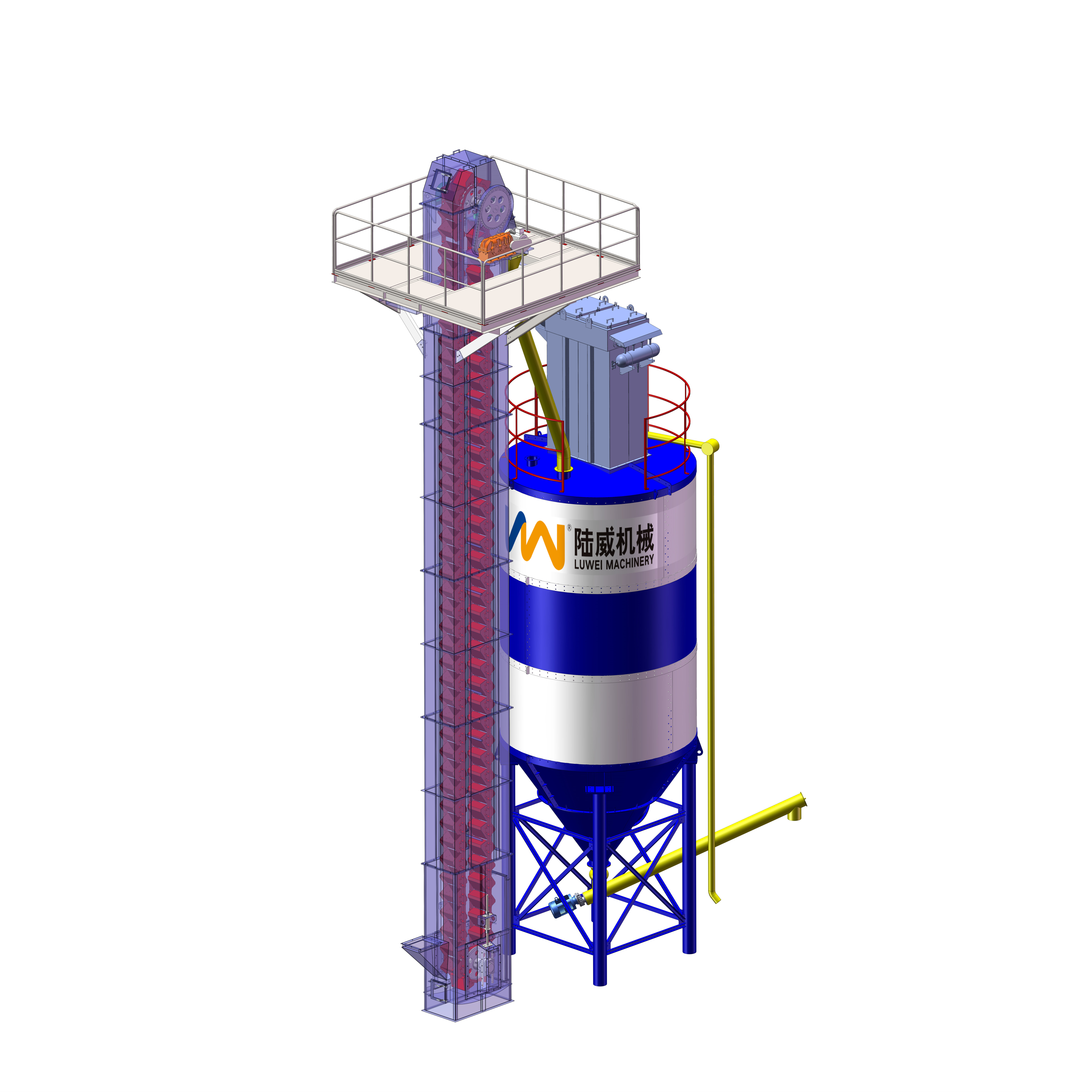

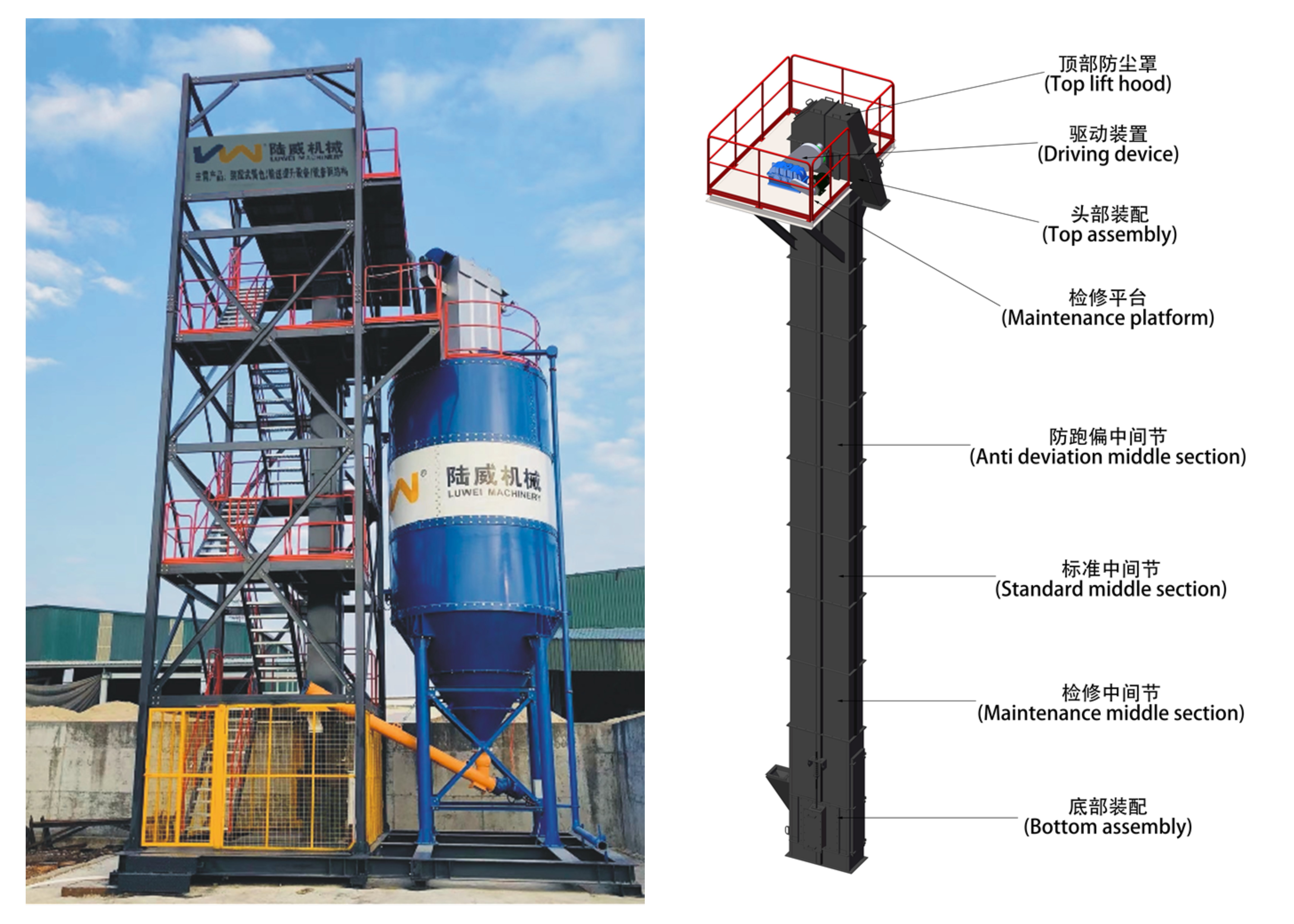

Plate chain vertical bucket elevator(high speed NSE type/NE type)

Applications and characteristics

1.The plate chain vertical bucket elevator can be used to lift various materials, including: ore, crushed stone, machine-made sand, coal, cement clinker, etc. It has a wide range of applications and less requirements on the types, characteristics and lumpiness of materials. Not only can improve powdery, granular and block materials, but also can upgrade materials with greater abrasiveness, and can upgrade materials with a temperature less than or equal to 250°C, and has a large conveying capacity, the lifting capacity can reach 800m³/h.

2.The lifting height is high, the chain speed of this series hoist is low, so the operation is stable, and the plate chain type high-strength wear-resistant chain is adopted, so it can reach a higher lifting height (up to 50 meters).

Good rigidity and long service life

The plate chain vertical bucket elevator adopts inflow feeding, and there is little squeezing and collision between materials. The design of this machine ensures that the material will not be sprinkled during feeding, lifting and unloading, which can prevent the material wear. The conveyor chain adopts a plate-chain type high-strength wear-resistant chain, which prolongs the service life of the chain and the hopper;High structural accuracy and shell flange welding make a better rigidity and appearance.

Energy saving and environmental protection

The plate chain vertical bucket elevator adopts inflow feeding, gravity-induced discharge and adopts densely arranged large-capacity hopper conveying, lowly speed and large lifting capacity, when the material is lifted, there is almost no return phenomenon, so the driving power is small, its shaft power is 25%-45% of the chain hoist after the theoretical calculation; Reliable sealing structure and less pollution to the environment; The advanced design principles ensure the reliable operation of the whole machine, more than 30,000 hours of trouble-free operation; Convenient operation and maintenance, few wearing parts, energy saving and maintenance, and low use costs.

Technical parameters:

| Plate Chain Vertical Bucket Elevator (High Speed NSE Type) Parameter | ||||||||

| Model | Lifting Capacity (m³/h) |

Bucket Distance (mm) |

Bucket Speed (m/min) |

Max. lumpiness of Material (mm) Percentage % |

||||

| 10 | 25 | 50 | 75 | 100 | ||||

| NSE50 | 63.48 | 304.8 | 66 | 35 | 30 | 20 | 15 | 10 |

| NSE100 | 170 | 400 | 66 | 35 | 30 | 20 | 15 | 10 |

| NSE150 | 148.6 | 400 | 66 | 35 | 30 | 20 | 15 | 10 |

| NSE200 | 198.1 | 400 | 66 | 35 | 30 | 20 | 15 | 10 |

| NSE250 | 247.6 | 400 | 66 | 50 | 35 | 25 | 20 | 20 |

| NSE300 | 317.1 | 400 | 66 | 50 | 35 | 25 | 20 | 20 |

| NSE400 | 423.8 | 500 | 66 | 50 | 35 | 25 | 20 | 20 |

| NSE500 | 530.3 | 500 | 66 | 50 | 35 | 25 | 20 | 20 |

|

|

| Plate Chain Vertical Bucket Elevator (NE Type) Parameter | ||||||||

| Model | Lifting Capacity (m³/h) |

Bucket Distance (mm) |

Bucket Speed (m/min) |

Max. lumpiness of Material (mm) Percentage % |

||||

| 10 | 25 | 50 | 75 | 100 | ||||

| NE15 | 15 | 203.2 | 29.8 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 35 | 304.8 | 30.1 | 90 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 304.8 | 30.1 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 400 | 31 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 170 | 400 | 31 | 130 | 105 | 80 | 65 | 55 |

| NE200 | 210 | 500 | 30 | 170 | 135 | 100 | 85 | 70 |

| NE300 | 320 | 500 | 30 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 380 | 600 | 30 | 205 | 165 | 125 | 105 | 90 |

| NE500 | 470 | 700 | 30 | 1240 | 190 | 145 | 120 | 100 |

| NE600 | 600 | 700 | 30 | 240 | 190 | 145 | 120 | 100 |

| NE800 | 800 | 800 | 30 | 275 | 220 | 165 | 135 | 110 |

Introduction of Reducer motor, chain wheel, chain.

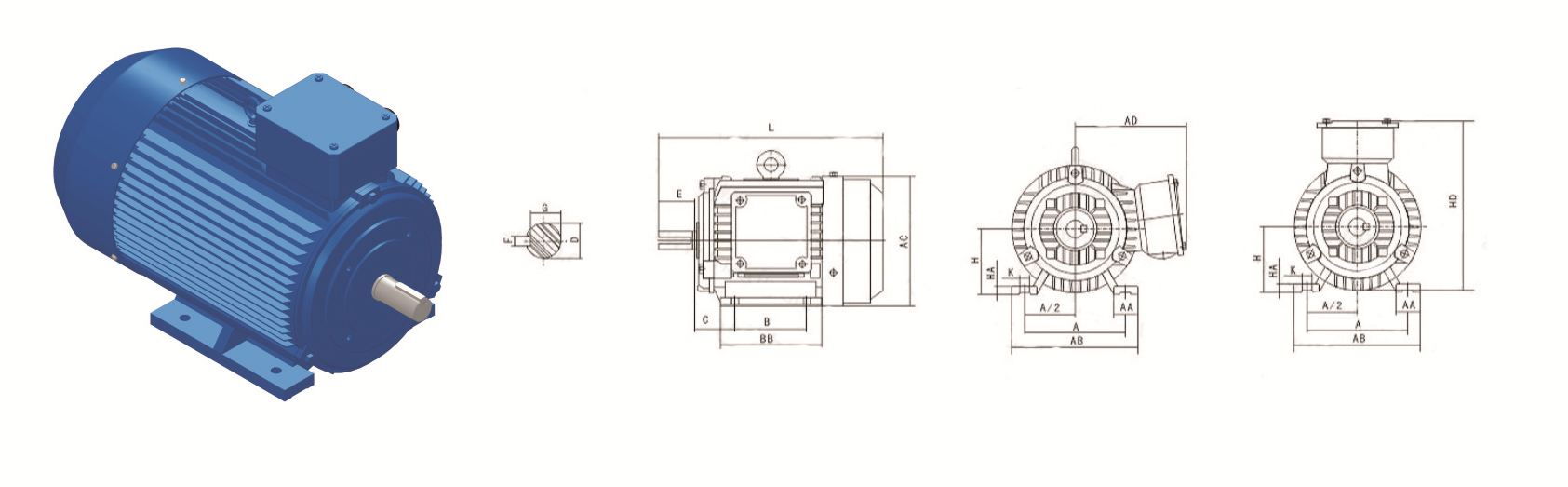

1.Luwei elevator equipped the YX3 series of Triple-phase asynchronous motor

Triple-phase asynchronous motor is one of the induction motor, It is a type of motor powered by 380V three-phase alternating current (phase difference 120 degrees) at the same time, because the rotor and stator rotating magnetic fields of a three-phase asynchronous motor rotate in the same direction and at different speeds, there is a slip ratio, so it is called a three-phase asynchronous motor. The speed of the rotor of the three-phase asynchronous motor is lower than that of the rotating magnetic field. The rotor winding generates electromotive force and current due to the relative movement between the magnetic field and the magnetic field, and interacts with the magnetic field to generate electromagnetic torque to realize energy conversion. Features: reliable operation, sturdy and durable, high operating efficiency.

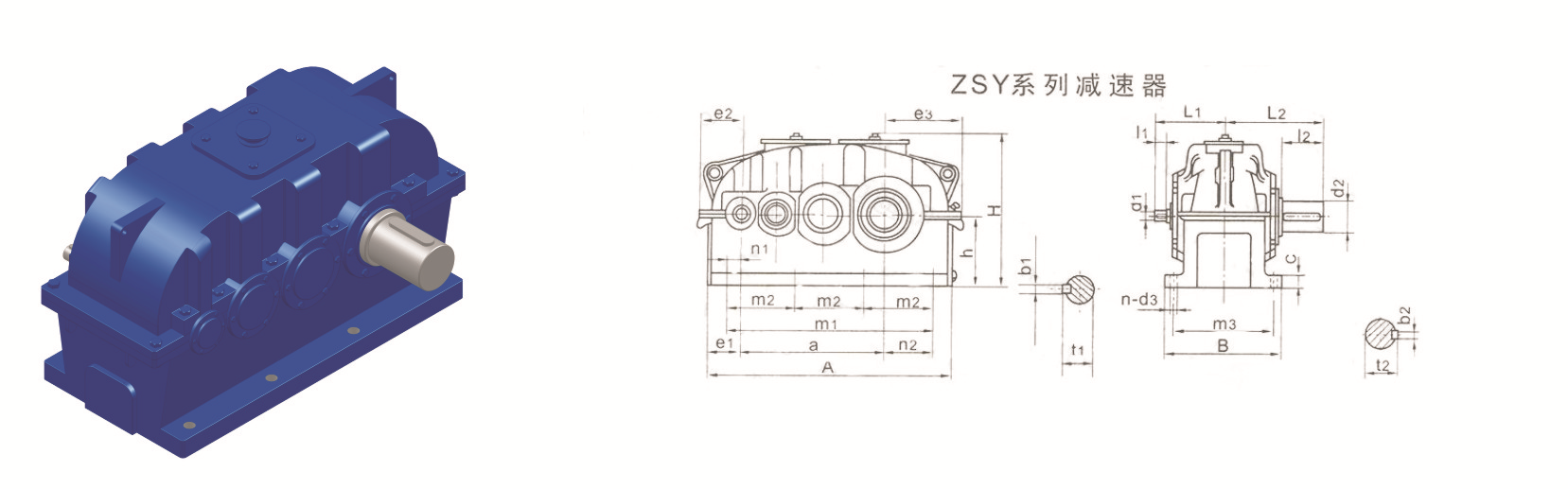

2.ZSY Hard tooth surface gearbox

ZSY reducer gears are made of high-quality alloy steel after carburizing and quenching. The tooth surface hardness reaches HRC54-62. The main parts have good interchangeability. It has small size, light weight, high precision, large load capacity and high efficiency. , Long life, high reliability, stable transmission, low noise, etc., are widely used in mining, building materials, construction machinery and other fields.

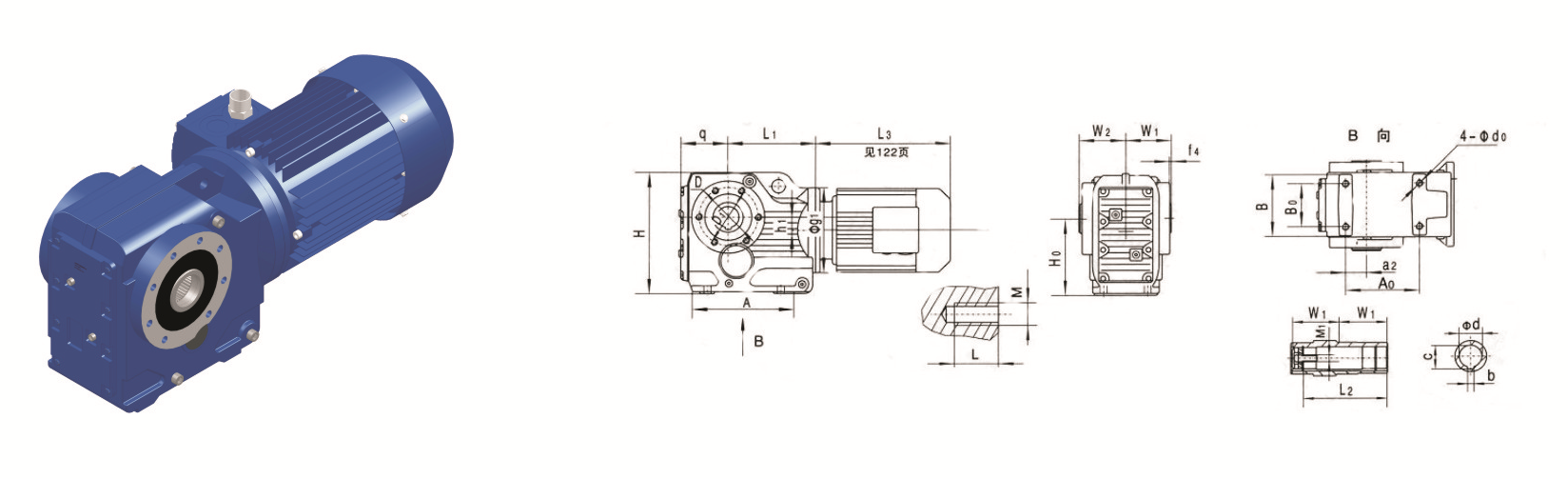

Geared motor:

The geared motor is an integrated body of the reducer and the motor (motor). It has the characteristics of space saving, reliability and durability, high overload capacity, low energy consumption, low vibration, low noise, high energy saving, long working life, and easy maintenance. Continuous work in corrosive and humid environment, widely used in mining, cement, construction and other fields.

Introduction of Reducer motor, chain wheel, chain.:

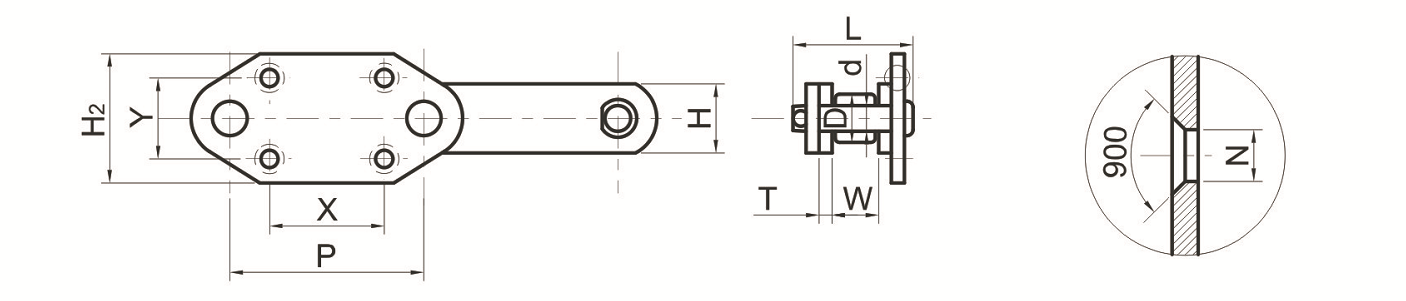

1.chain wheel specification sheet

| NE Type | ||||||||||||

Chain No. |

Pitch |

Inside width |

Roller dia. |

Plate | Pin | Attachment dimensions |

Ultimate tensie strength |

|||||

Height |

Thick |

Dia. |

L |

|||||||||

| P | W | D | H | T | D | L | H2 | N | X | Y | KN | |

| mm | ||||||||||||

| NE15-101.60 | 101.60 | 27.00 | 26.50 | 35 | 6 | 11.50 | 70.00 | 41.50 | 12 | 40 | 45 | 90 |

| NE50-152.40 | 152.40 | 37.00 | 35.71 | 48 | 8 | 15.50 | 90.00 | 110.00 | 14 | 75 | 70 | 230 |

| NE100-200 | 200.00 | 51.00 | 44.50 | 58 | 10 | 19.10 | 110.60 | 125.00 | 18 | 100 | 80 | 304 |

| NE150-200 | 200.00 | 57.60 | 48.50 | 75 | 10 | 22.23 | 117.50 | 125.00 | 18 | 100 | 80 | 520 |

| NE150-200-A | 200.00 | 57.60 | 63.50 | 85 | 12 | 31.75 | 129.50 | 125.00 | 18 | 100 | 80 | 750 |

| NE200-250 | 250.00 | 67.40 | 63.50 | 90 | 12 | 31.75 | 139.30 | 150.00 | 18 | 140 | 100 | 750 |

| NE300-250 | 250.00 | 75.00 | 75.00 | 100 | 16 | 35.00 | 126.00 | 150.00 | 18 | 140 | 100 | 980 |

| NE400-300 | 300.00 | 75.00 | 75.00 | 100 | 16 | 35.00 | 126.00 | 180.00 | 22 | 170 | 120 | 980 |

2.chain specification sheet

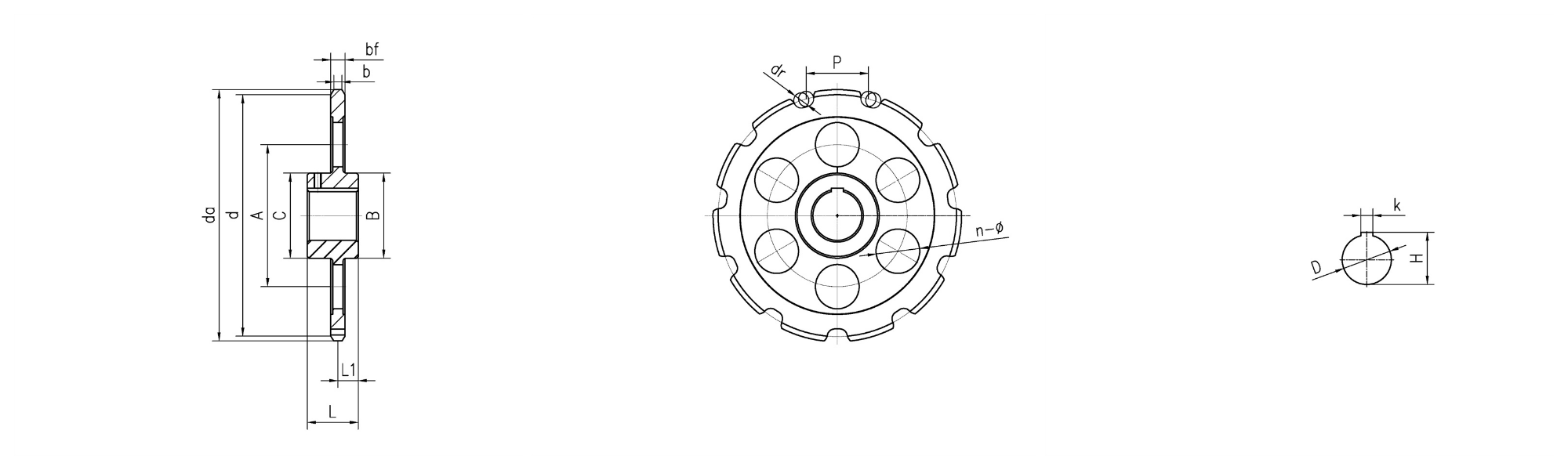

| Name | Model | ||||||

| NE15 | NE30 | NE50 | NE100 | NE150 | NE200 | NE300 | |

| Addendum circle diameter(da) | φ515 | φ612 | φ612 | φ740 | φ740 | φ941 | φ936 |

| Diameter of index circle(d) | φ488.67 | φ588.8 | φ588.8 | φ709.89 | φ709.89 | φ887.37 | φ887.37 |

| Tooth root circle diameter(df) | φ462.17 | φ552.8 | φ552.8 | φ665.39 | φ661.4 | φ823.87 | φ815.37 |

| Center distance of weight-reducing hole(A) | φ290 | φ355 | φ355 | φ417 | φ345 | φ450 | φ450 |

| Outer diameter of wheel hub short end(B) | φ150 | φ210 | φ210 | φ250 | φ270 | φ330 | φ340 |

| Outer diameter of long end of wheel hub(C) | φ150 | φ210 | φ210 | φ250 | φ270 | φ330 | φ340 |

| Tooth width(bf) | 21 | 30 | 30 | 42 | 42 | 60 | 70 |

| Short end length(L1) | 50 | 50 | 50 | 71 | 60 | 110 | 120 |

| Hub length(L) | 130 | 150 | 150 | 170 | 190 | 235 | 250 |

| Diameter of shaft hole(D) | φ87 | φ136 | φ136 | φ146 | φ174 | φ205 | φ230 |

| Key width(K) | 25 | 36 | 36 | 36 | 40 | 50 | 50 |

| Key deep(H) | 92.4 | 144.4 | 144.4 | 154.4 | 183.4 | 216.4 | 241.4 |

| Weight reducing hole diameter(n-φ) | 6-φ80 | 6-φ90 | 6-φ90 | 6-φ130 | 6-φ60 | 6-φ80 | 6-φ80 |

| Pitch(P) | 101.6 | 152.4 | 152.4 | 200 | 200 | 250 | 250 |

| Roller diameter(dr) | φ26.5 | φ36 | φ36 | φ44.5 | φ48.5 | φ63.5 | φ72 |

| Number of teeth(Z) | 15 | 12 | 12 | 11 | 11 | 11 | 11 |

Factory main production equipment:

Scan and follow Lu Wei

Scan and follow Xiang Hao

Scan and follow Zhi Xiang

Xiamen Luwei Prefabricated

Steel Structure Co., Ltd Ltd.

Service Hotline:

+86 592-7072928 / +86 18150889219 (Tina Ye) (Overseas)

E-mail:tina.ye@xmlwjx.com

Registered address of the company:

Office Building 3rd Floor, No.608, Xinxia

South Road, Xinxu Town, Xiang'an District, Xiamen City

Factory Address:

E3 workshop, Factory 2nd Floor, No.608, Xinxia South Road, Xinxu Town, Xiang'an District, Xiamen City

Page Copyright: Xiamen Luwei Prefabricated Steel Structure Co., Ltd Ltd. 闽ICP备10205934号

Friendly Link: Alibaba